- Home

- Standard Products

- Temperature Sensors & Accessories

- Thermocouple Temperature Sensors

- Pt100 Resistance Thermometer Temperature Sensors

- Infrared Pyrometers & Cameras from DIAS

- Temperature Sensor Connectors, etc.

- Thermocouple & Pt100 Cable

- Thermocouple Welders

- Hand-held Measurement Instruments

- Digital Thermometers

- Infrared Thermometers

- Hygrometers

- Humidity Instruments from Rotronic

- Digital Stop-Clocks & Timers

- Digital Tachometers

- Standalone Data Loggers from Hobo

- PC Based Data Loggers from Pico

- Hand-held Data Loggers

- Almemo Universal Measurement Systems

- Calibration Equipment

- Hand-held Process Calibrators

- Dry-Well Block Calibrators

- Portable Calibration Furnaces

- Portable TUS Survey Recorders

- Process Control & Instrumentation

- Temperature/Process Controllers, stocked

- Temperature/Process Indicators, stocked

- Temperature/Process Recorders, stocked

- InstCube Wall Mount Temperature Units

- ABB Controller, Indicator, Recorder ranges

- Eurotherm Controller, Recorder ranges

- Omron Controller, Indicator ranges

- Watlow Controller, Data Logger ranges

- Portable Cased Temperature Recorders

- Controller & Recorder Parts & Accessories

- Bespoke Temperature Sensors

- Calibration Services

- Applications

- Company

- News

- Christmas Message 2025

- We are now ISO 45001: 2018 & ISO 14001: 2015 Accredited

- 1st Anniversary as an Employee Ownership Trust

- TMS Europe announce transition to Employee Ownership Trust (EOT) status

- New TMS website & TMS Webshop

- Important COVID-19 Coronavirus Announcement

- Vacancy for Calibration Engineer

- 50,000 UKAS Certificates Issued

- ABB RVG200 Recorder – Custom Views & Remote Operation

- SNOL Lab Ovens now with 2 year warranty

- Thermocouple Protection Sheaths

- Vacancies at TMS Europe Ltd

- New Laboratory and offices

- UKAS Calibrated Incubator, Vaccine Fridge & Freezer Thermometer

TMS Europe Ltd is a UKAS accredited calibration laboratory No.0461, as defined in our Schedule of Accreditation. As a UK manufacturer we're a member of Made in Britain.

TMS Europe Ltd is a UKAS accredited calibration laboratory No.0461, as defined in our Schedule of Accreditation. As a UK manufacturer we're a member of Made in Britain.Thermocouple Colour Codes & Tolerances

Thermocouple Colour Codes & Tolerances

Thermocouple temperature sensors can be made with various conductor materials for different temperature ranges and output characteristics. Over the years these have been standardised with defined temperature difference vs millivolt output relationships.These established thermocouple “Types”, e.g. “Type K”, (sometimes confusingly referred to as “thermocouple calibrations”) are not compatible with each other and must have their own connecting cables and measurement instruments configured for that Type. Because of the way thermocouples work it is paramount that polarity (connection of positive to positive and negative to negative) is always followed through all connections.

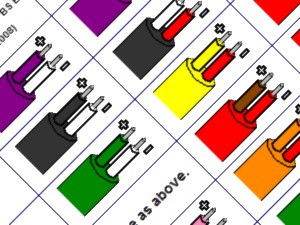

Thermocouple Extension & Compensating Cable Colour Codes

The table below shows the most commonly encountered colour codes used on thermocouple leads and connectors. These are used to identify the Type and positive and negative wires. It is important to recognise the unfortunate use of the same colours for outer sheaths and connectors on different thermocouple types under different standards. Other colour coding systems also exist but are not shown below, these include former French, former German and Japanese.

| Thermocouple Type | IEC* / British (IEC 60584-3:2007 / BS EN 60584-3:2008) | ANSI / American (ANSI MC96.1 / ASTEM E230) | Former British (BS 1843:1952) | Former Sheffield (Bastardised system, 1950 onwards, developed by Land Pyrometers Ltd) |

| Type E |  |  | N/A | |

| Type J |  | |||

| Type K Extension |  |  | ||

| Type K Compensating | Same as above. | Same as above. | ||

| Type N |  |  | N/A | |

| Type R & Type S |  | |||

| Type T |  |  | N/A | |

| Type B | N/A. Uses uncompensated (copper) cable. Connectors are often white. | |||

Thermocouple Temperature Ranges

The table below shows the defined temperature ranges for thermocouple types. The IEC standard defines Class Tolerances for initial accuracy over a given temperature range. Outside these temperatures the manufacturing accuracy is unknown and if a thermocouple is used outside these temperatures it may de-calibrate (permanently lose accuracy) at a much faster rate.

| Thermocouple Type | Temperature Range (°C) | ||||

| Short Term Use | Continuous Use | Class 1 Tolerance* | Class 2 Tolerance* | Class 3 Tolerance* | |

| Type E | -40 to +900 | 0 to +800 | -40 to +800 | -40 to +900 | -200 to +40 |

| Type J | -180 to +800 | 0 to +750 | -40 to +750 | -40 to +750 | N/A |

| Type K | -180 to +1300 | 0 to +1100 | -40 to +1000 | -40 to +1200 | -200 to +40 |

| Type N | -270 to +1300 | 0 to +1100 | -40 to +1000 | -40 to +1200 | -200 to +40 |

| Type R | -50 to +1700 | 0 to +1600 | 0 to +1600 | 0 to +1600 | N/A |

| Type S | -50 to +1750 | 0 to +1600 | 0 to +1600 | 0 to +1600 | N/A |

| Type T | -250 to +400 | -185 to +300 | -40 to +350 | -40 to +350 | -200 to +40 |

| Type B | 0 to +1820 | +200 to +1700 | N/A | +600 to +1700 | +600 to +1700 |

Thermocouple Tolerances: IEC 60584-2:1982 / BS EN 60584-2:1993

*Thermocouples of this tolerance class can be used outside this range, but no tolerance is defined outside these limits.

Thermocouple Materials & Accuracy Tolerances

| Thermo- couple | Material ( + / - ) | Class 1 Tolerance | Class 2 Tolerance | Class 3 Tolerance |

| Type E | Chromel / Constantan | -40 to +375 : ±1.5°C +375 to +800 : ±0.4% | -40 to +333 : ±2.5°C +333 to +900 : ±0.75% | -200 to -167 : ±1.5% -167 to +40 : ±2.5°C |

| Type J | Iron / Constantan | -40 to +375 : ±1.5°C +375 to +750 : ±0.4% | -40 to +333 : ±2.5°C +333 to +750 : ±0.75% | N/A |

| Type K | Chromel / Alumel | -40 to +375 : ±1.5°C +375 to +1000 : ±0.4% | -40 to +333 : ±2.5°C +333 to +1200 : ±0.75% | -200 to -167 : ±1.5% -167 to +40 : ±2.5°C |

| Type N | Nicrosil / Nisil | -40 to +375 : ±1.5°C +375 to +1000 : ±0.4% | -40 to +333 : ±2.5°C +333 to +1200 : ±0.75% | -200 to -167 : ±1.5% -167 to +40 : ±2.5°C |

| Type R & Type S | Platinum–Rhodium / Platinum | 0 to +1100 : ±1°C +1100 to +1600 : ±(1°C+0.003* (t°C-1100°C))°C | 0 to +600 : ±1.5°C +600 to +1600 : ±0.25% | N/A |

| Type T | Copper / Constantan | -40 to +125 : ±0.5°C +125 to +350 : ±0.4% | -40 to +133 : ±1°C +133 to +350 : ±0.75% | -200 to -67 : ±1.5% -67 to +40 : ±1°C |

| Type B | Platinum–Rhodium / Platinum–Rhodium | N/A | +600 to +1700 : ±0.25% | +600 to +800 : ±4°C +800 to +1700 : ±0.5% |

Thermocouples & RTDs Accuracy Tolerance Comparison

The table below contains the manufacturing tolerances for different thermocouple types and Pt100s classes at different temperatures. These are ± (+/-) values, so a Class 1 Type K thermocouple at 500°C is ±2°C, so could read anything between 498°C and 502°C and be within manufacturing tolerance. But remember, with use thermocouples will de-calibrate and drift outside these tolerances, which is why calibration is so important.

Select Temperature Range:

| Thermocouple | Pt100 RTD | |||||||||||||||

| Type: | E | J | K | N | R & S | T | B | |||||||||

| Class: | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 2 | 3 | A | B |

| - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

Thermocouple Extension & Compensating Cable Accuracy Tolerances

| Thermocouple & Cable Type | Cable Ambient Temperature Rating | Tolerance (Constant µV / Example °C) | Example Measured Temperature | |

| Class 1 | Class 2 | |||

| Type E Extension (EX) | -25°C to +200°C | ± 120 µV / ± 1.5 °C | ± 200 µV / ± 2.5 °C | 500°C |

| Type J Extension (JX) | -25°C to +200°C | ± 85 µV / ± 1.5 °C | ± 140 µV / ± 2.5 °C | 500°C |

| Type K Extension (KX) | -25°C to +200°C | ± 60 µV / ± 1.5 °C | ± 100 µV / ± 2.5 °C | 900°C |

| Type K Compensating A (KCA) | 0°C to +150°C | – | ± 100 µV / ± 2.5 °C | 900°C |

| Type K Compensating B (KCB) | 0°C to +100°C | – | ± 100 µV / ± 2.5 °C | 900°C |

| Type N Extension (NX) | -25°C to +200°C | ± 60 µV / ± 1.5 °C | ± 100 µV / ± 2.5 °C | 900°C |

| Type N Compensating (NC) | 0°C to +150°C | – | ± 100 µV / ± 2.5 °C | 900°C |

| Type R Compensating A (RCA) | 0°C to +100°C | – | ± 30 µV / ± 2.5 °C | 1000°C |

| Type R Compensating B (RCB) | 0°C to +200°C | – | ± 60 µV / ± 5.0 °C | 1000°C |

| Type S Compensating A (SCA) | 0°C to +100°C | – | ± 30 µV / ± 2.5 °C | 1000°C |

| Type S Compensating B (SCB) | 0°C to +200°C | – | ± 60 µV / ± 5.0 °C | 1000°C |

| Type T Extension (TX) | -25°C to +100°C | ± 30 µV / ± 0.5 °C | ± 60 µV / ± 1.0 °C | 300°C |

| Type B (Copper / Uncompensated) | 0°C to +100°C | ± 40 µV / ± 3.5 °C | 1400°C | |